Planters

The benchmark for Planter design, a completely bespoke service to any shape, size, material or finish

Superbly engineered. Beautifully finished. Completely bespoke.

A design perfected over 20 years that is perfectly scalable and adaptable to your exact requirements, all to an exquisite seamless finish.

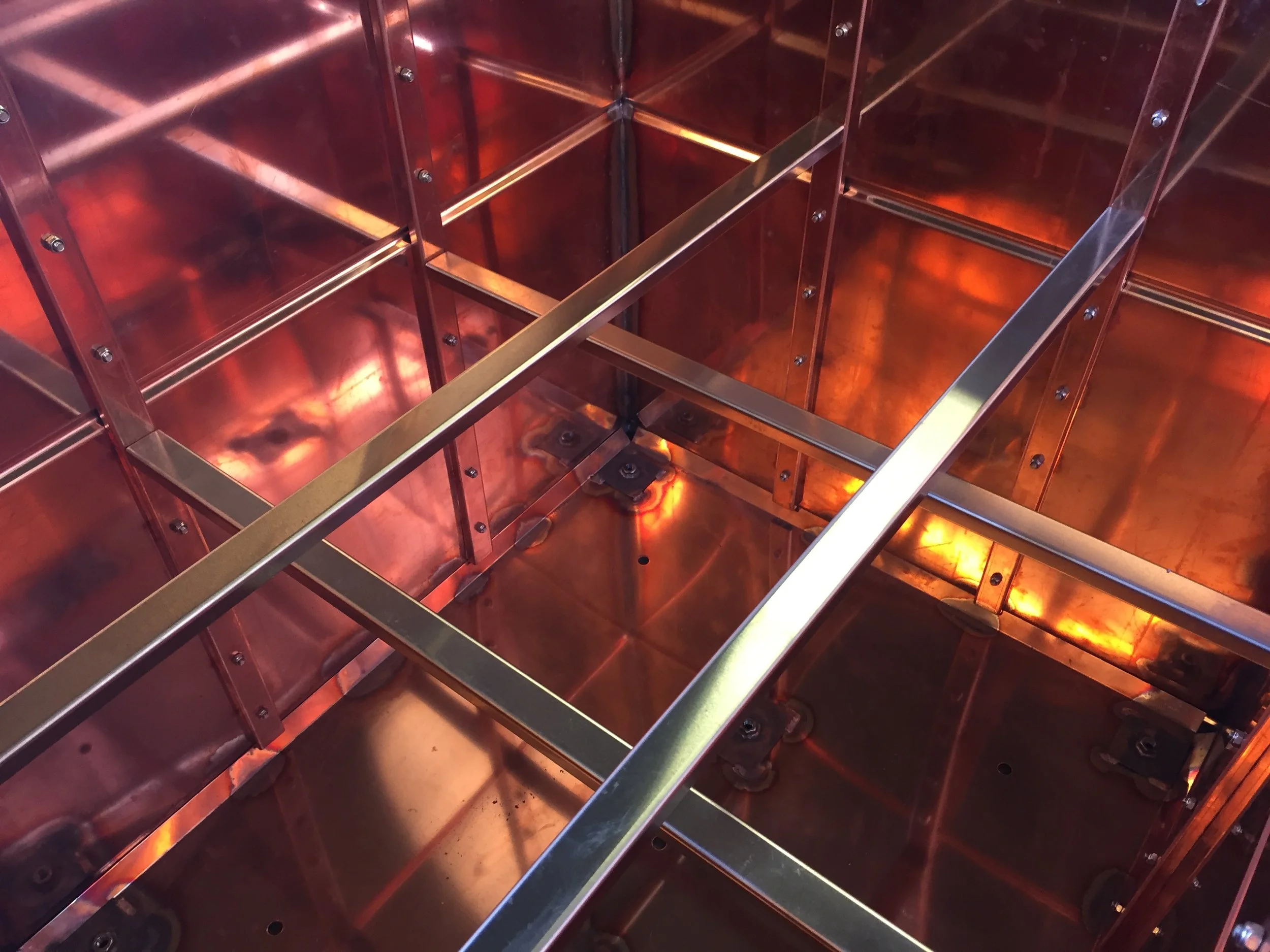

A folded lip detail, drainage holes, and internal bracing as well as adjustable feet with guying points are all included as standard.

In addition to galvanised steel, planters can be supplied in Aluminium, Corten and Stainless Steel as well as Brass, Bronze or Copper. Any surface finish can be provided; Powder coating to any standard RAL colour, or more exotic metallic based colours, galvanised and zinc finishes as well as patinated and faux finishes. Zinc or lead wrapped systems are also available.

Galvanised Planters Primrose Hill

Explore our Planter Projects

Galvanised Planters City of London

Planters and Seating St James's

Galvanised Planters Primrose Hill

Interior Planters & Seating St James's

Planters and Greenwall The Strand

Galvanised Planters Smithfield's

Planters and Water Feature Hertfordshire

Bronze Planters Jermyn Street

Corten Planters Primrose Hill

Bronze Planters Charles II Street

Faceted Planters Notting Hill Gate

Powder Coated Planters Hammersmith

Stone Clad Planters Mayfair

Aluminium Planters Soho

Terrace Screens and Planters Mayfair

Galvanised Planters Herne Hill

Copper Planters Chelsea

Corten Edging Planter London

Window Planters Belgravia

Circular Planters Islington

Planters and Water Features Notting Hill

Terrace Planters Paddington

Planters and Window Boxes Chelsea

Lead Planters Covent Garden

Planters and Balustrade Notting Hill

Roof Terrace Planters Notting Hill

Interior Planters City of London

Tree Planters Hyde Park

Street Planters Buckingham Gate

Bronze Planter Chester Terrace

Galvanised Planters Canary Wharf

Stainless Steel Planter Centrepoint

Powder Coated Planters Docklands

Curved Planters Merchant Square

Planted Structure Cambridge Gate

Planters and Screens Mayfair

Galvanised Planters Hereford

Stainless Planters Centrepoint

Powder Coated Planters West Sussex

Shop Front Planters London

Interior Planters Triton Street

Entrance Planters Newquay

Powder Coated Planters Sussex

Street Planters Haddington

Bespoke Planters Cornwall

Bespoke Planters Hammersmith

Stainless Steel Planters Dublin

Galvanised Planters London Bridge